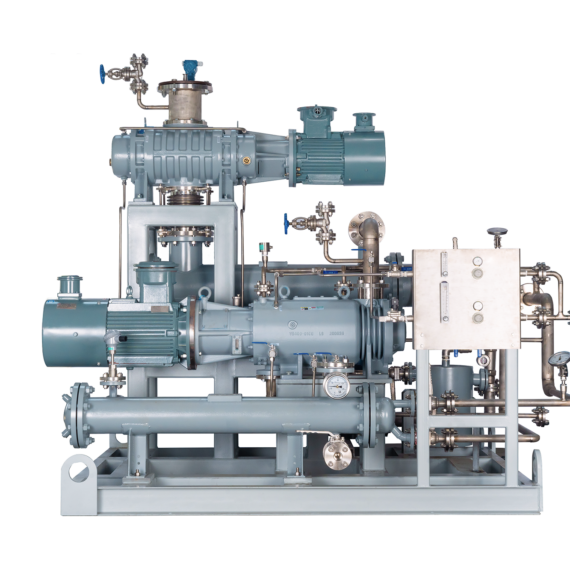

Industry Leader in Vacuum Pump Systems

FOLLOW @NESPUMPS ON INSTAGRAM

{"error":{"message":"Error validating access token: The session has been invalidated because the user changed their password or Facebook has changed the session for security reasons.","type":"OAuthException","code":190,"fbtrace_id":"ANZEeP7KU3gxGL9aOsAYaPA"}}